Toyota Is Moving A 700-Ton Prewar Press Machine Halfway Around The World

Toyota closed its São Bernardo Plant in November 2023, marking the end of its first overseas production facility. The closure caps off a period of continuous car production in São Paolo, Brazil, lasting over 60 years. The plant was home to a Komatsu 700-ton press that predates Toyota’s carmaking business itself. And now that the plant has closed, Toyota is bringing the press machine back home to Japan, where it will keep making spare parts and be used to train workers.

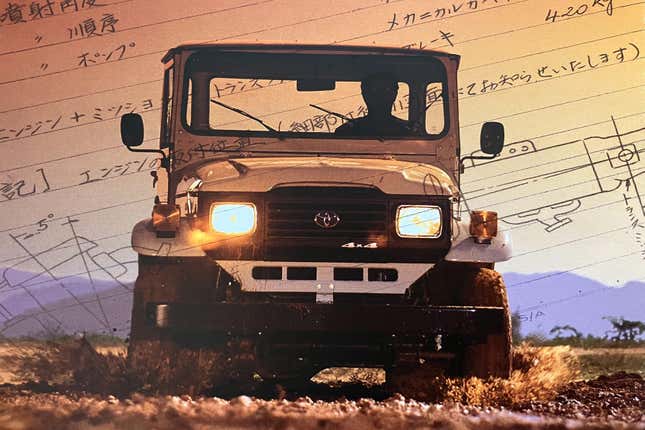

The Toyota Land Cruiser Is Back Baby!

The Komatsu press has been in use for 89 years, according to the Toyota Times. The machine was bought by the Toyoda Automatic Loom Works Automobile Department in 1934, and was installed in a plant in Japan’s Aichi Prefecture. Toyota was founded in 1937, so the press is older than its parent company.

Photo: Toyota

The Komatsu press operated at the automaker’s Koromo plant, which was later renamed the Honsha Plant. It was moved to Brazil in 1962 when Toyota do Brasil’s São Bernardo plant came online. There, the press helped Toyota make a name for itself in South America with the Bandeirante model, which roughly translates to pioneer or scout. That was the Portuguese name of Toyota’s Brazilian Land Cruiser, produced in the country from 1962 until 2001.

Photo: Toyota

After production of the Bandeirante ended in Brazil, the Komatsu press kept making parts for Corolla and Hilux models through the 2020s. Toyota has closed the plant that where the press operated, citing a need to consolidate production in Brazil across three other other plants in the country.

Some workers were given the option to relocate or retire, but the Komatsu press will keep working at its original home in the Honsha plant in Japan. Toyota’s Latin American and Caribbean Region CEO, Masahiro Inoue, told the Toyota Times that the press helped start the company as we know it today:

Inoue says, “It’s unbelievable that a Japanese company made and purchased such a large item before the war. It must have been incredibly expensive. I speculate that it was largely funded by the money earned from selling Toyoda Automatic Loom Works patents to a British company, which also funded the establishment of Toyota Motor Corporation. I believe it must have been expensive.”

After consultation with Chairman Akio Toyoda, the company decided to preserve this historically valuable press machine through “functional conservation” (maintained in a production-capable state).

The machine will be reinstalled in the same location within the Honsha Plant where it stood 60 years ago, continuing its role in producing spare parts. Additionally, it is slated to be used in training workers in die maintenance and other related tasks.

The 700-ton press played a key role in Toyota’s history, which is why the company is transporting it across the Pacific Ocean from Brazil to Japan. The São Bernardo plant is even reportedly the birthplace of the Toyota Production System. Both the press and the factory where it operated represent a series of firsts for Toyota: the plant was the first overseas production location that the company opened; and the Bandeirante was its first production vehicle that was made outside of Japan. That may be why the press will live on.

Photo: Toyota

Photo: Toyota