Tesla’s Cheapest Model 3 Is The First Victim Of Chinese Tariffs

Good morning! It’s Thursday, October 3, 2024, and this is The Morning Shift, your daily roundup of the top automotive headlines from around the world, in one place. Here are the important stories you need to know.

The GM EV1 Was a Great First Effort With No Follow-Up

1st Gear: Tesla Kills Its Cheapest Car

This was an important week for Tesla as it announced its sales for the third quarter of 2024. Thankfully, its sales were up at the electric car maker, but not in the way experts had predicted and that meant the company’s stock still isn’t doing great. While all that was going on, the automaker made another step that’s sure to irritate investors and buyers, it killed off its cheapest model.

As of this week, Tesla has taken the Model 3 Standard Range Rear-Wheel Drive model down from its website, reports Reuters. The car, which boasted up to 272 miles of range, started at $38,990 and was the company’s most affordable model:

The Model 3 Standard Range Rear-Wheel Drive, priced at $38,990, uses lithium iron phosphate (LFP) battery cells sourced from China.

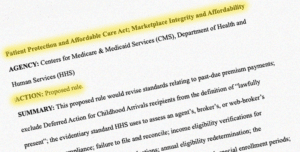

The U.S. recently announced higher tariffs on Chinese imports, including a 100% tariff on EVs and 25% on EV batteries and key minerals.

Additionally, vehicles that contain Chinese-made components, such as LFP battery cells, are ineligible for the $7,500 federal tax credit provided by the government.

Tesla’s Model 3 Long Range Rear-Wheel Drive is now its most affordable offering in the United States, priced at $42,490.

The fact that the standard range edition of the Model 3 didn’t qualify for federal tax credits launched as part of the Inflation Reduction Act means that the impending Chinese tariffs were probably just the final nail in its coffin. Those tariffs are something that Tesla boss Elon Musk hasn’t been quiet about since they first emerged, with the CEO even going so far as to oppose such measures, I wonder why?

However, the demise of the budget-friendly Model 3 just shows the wide-reaching impact that the tariffs could have on America’s auto industry, with many businesses sourcing cheaper components from China to fit into their cars. It’s for this reason that experts recently warned that the impending tariffs could make buying new cars in the U.S. harder and more expensive.

2nd Gear: Toyota Delays U.S. EV Production

While Tesla has been canceling its cheap electric models, Japanese automaker Toyota has been pushing back some of its electric ambitions. The Corolla maker announced today that it will delay its plans for U.S.-made EVs until 2026, reports Bloomberg.

Toyota initially planned to offer American-made EVs from 2025, reports Bloomberg. However, the automaker will now not roll out its fleet of U.S. electric models until at least 2026, when it aims to have seven electric cars on sale in the Land Of The Free:

The Japanese carmaker initially targeted late next year to begin output of a three-row, battery-powered SUV at an assembly plant in Georgetown, Kentucky, but a company spokesman said Wednesday that has slipped by a few months into the following year.

Toyota is still committed to making the as-yet-unnamed SUV in Kentucky from early 2026 and another unspecified all-electric SUV at a factory in Princeton, Indiana, starting later that year, he said.

The planned expansion of Toyota’s EV lineup in the US from the current two vehicles to as many as seven comes at a time when demand for battery-powered vehicles has slowed. The US rollout is part of a broader goal to sell 1.5 million EVs globally by 2026. To help reach that, Toyota is building a lithium-ion battery plant in North Carolina that is expected to start up in 2025.

The delay to Toyota’s American EVs follows a tempering of expectations from the brand for its electric ambitions. Last month, the automaker cut its EV output targets by about a third. The company now aims to produce about a million EVs by 2026, down from the 1.5 million that it was initially aiming to produce by the end of the year.

Toyota has repeatedly shown a reluctance to embrace electrification, instead opting to expand its offering of hybrid models like the Corolla and Prius. That strategy appeared to be paying off for the automaker earlier this year, when it posted rising sales and profits as a result of the increased attention on hybrid cars.

3rd Gear: Hurricane Helene Shuts Mines Crucial For Microchips

The trail of devastation left by Hurricane Helene after it swept across the U.S. is only just being fully realized, with houses flooded, roads ripped up and EVs bursting into flames as a result of all the salt water that flooded some states. Now, it’s emerged that the storm may wreak havoc on the auto industry after it shuttered a factory that produces elements essential for microchips.

When the immense storm ripped through North Carolina last week, it destroyed facilities in the region that are operated by two companies that mine for essential minerals required for microchip production, reports Automotive News. As a result of the damage caused, the facilities are now closed, which could impact the production of chips essential for America’s auto industry:

Sibelco Group and The Quartz Corp. shut down their operations in Spruce Pine, N.C., about 50 miles northeast of Asheville, on Sept. 26 because of the hurricane, which ravaged parts of the Southeast with intense flooding. The town is one of the only sites in the world to contain high-purity quartz, which is key to making semiconductors, according to author Ed Conway, who wrote “Material World: The Six Raw Materials That Shape Modern Civilization.”

Should it persist, the halt in operations could affect global supply chains that depend on semiconductors for use in vehicles, phones, solar panels and other technologies.

“We’re listening to worried voices on this topic,” said Sam Fiorani, vice president of global vehicle forecasting at AutoForecast Solutions, which monitors the impact of semiconductor availability on the auto industry. “It’s far too early to ring the alarm bells, but making sure the supply chains are adequately provided for is definitely on everybody’s radar at the moment.”

It’s too early to know what impact the shutdown could have, but the last time American automakers faced a shortage of microchips it was not good. A shortage of computer chips brought on by the impact of the Covid-19 pandemic meant that all kinds of cars were delayed or shipped with features missing.

Just three years ago, the semiconductor shortage meant that Ford had to cut production and temporarily shutter some plants, Cadillac cut features from some Escalade models while it rummaged for parts and the Ford Bronco had features cut initially.

4th Gear: Hybrids Are Even Winning At BYD

Hybrids are so hot right now, with Toyota banking big on their popularity, General Motors pledging to launch more hybrid offerings and automakers around the world backtracking on their EV goals in favor of hybrid power. Now, it’s emerged that hybrid options are even selling like hotcakes for one of the world’s biggest EV makers: BYD.

The Chinese company this week announced that it sold 1.6 million hybrid models between January and September 2024, reports Reuters. In contrast, the automaker shipped 1.2 million EVs in the same period. Last year, EVs accounted for more than half of BYD’s sales:

Hybrids are moving into pole position at BYD. The $122 billion auto- and battery maker is on track to sell more models powered by both a battery and an old-school motor than pure electric vehicles this year. Exports could turbocharge the trend, but competition, climate goals and protectionism complicate efforts to ride a global hybrids boom.

From January to September, BYD sold 1.6 million hybrids and 1.2 million purely battery-powered cars; a year earlier, more than half of its sales were in the latter category. China drives the change, but the next growth spurt is coming from overseas. Although BYD exported a negligible number of these products last year, in the first half they represented about 40% of shipments, CLSA estimates.

This is part of something bigger. Exports of China-made hybrids have roughly doubled every year since 2020, per the International Trade Centre, rising over 200,000 last year. China’s combined exports of all-electric powertrains totalled around 1.5 million in 2023.

Due to fears around Chinese EVs here in the States, you can’t buy a BYD vehicle over here, whether it’s battery-powered or packed with a hybrid powertrain. However, the automaker has been increasing its global footprint in recent years with its budget EV offerings taking Europe and Australia by storm.

With hybrids in its range too, and the popularity those cars are currently witnessing, could BYD continue its meteoric rise in popularity and become a real threat to the superiority of legacy automakers like Ford and Toyota? Only time will tell.

Reverse: It’s October 3

Mean Girls – It’s October 3rd

On The Radio: Broken Bells – ‘October’

Broken Bells – October (Audio)