How Pirelli is improving its road tires from Formula 1 racing

AUSTIN, Texas — Formula 1 is on a nonstop popularity upswing in the U.S. as more and more races continue to be added to the docket before promptly selling out. New fans or old fans alike are familiar with the never-ending conversation around tires. Choices about which tire to run can make or break your GP, and Pirelli is always at the center of said conversations. This story isn’t about racing tires, though. Instead, we’re taking a short dive into what Pirelli’s involvement in Formula 1 has done for improving its road tires.

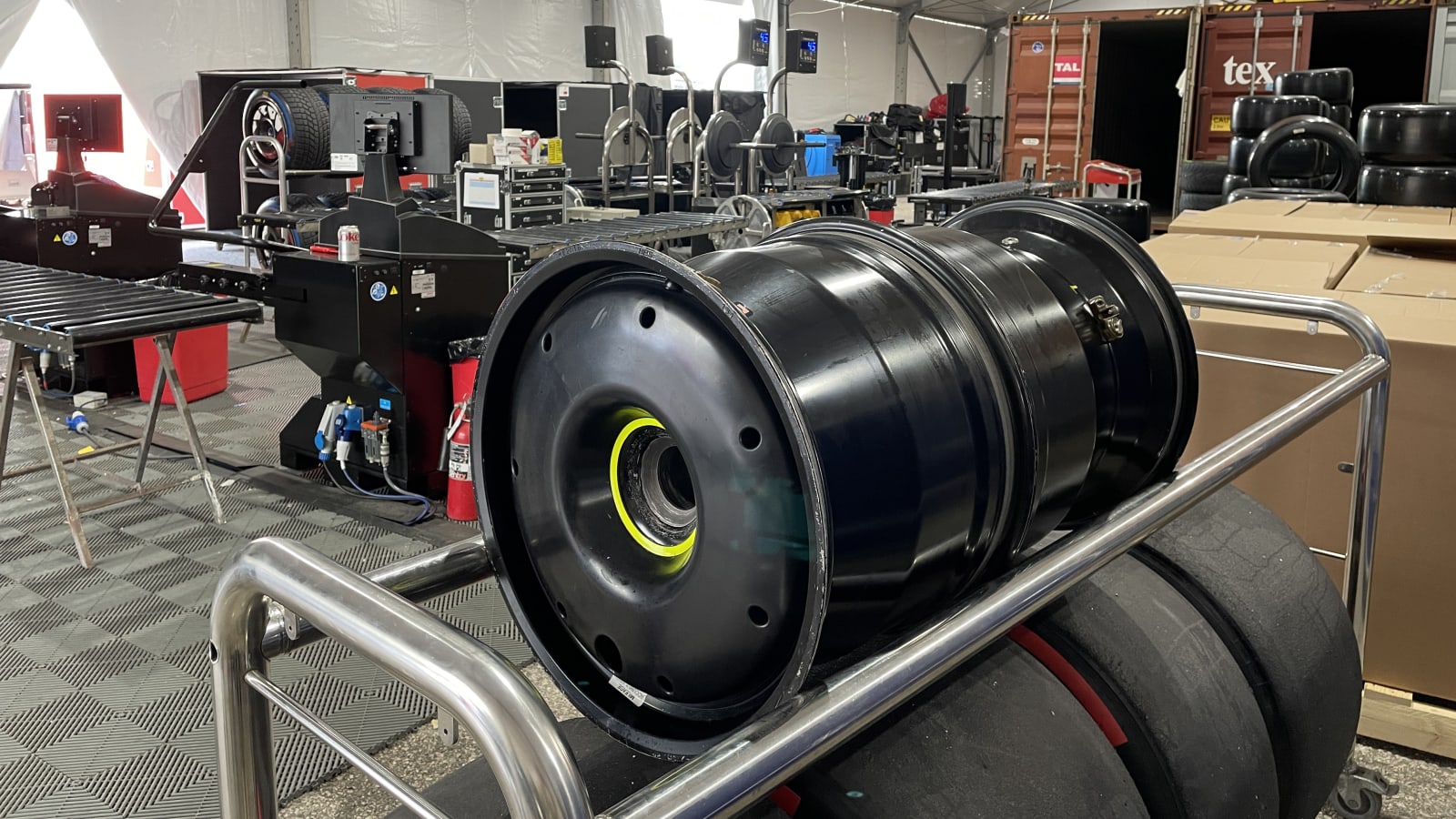

Pirelli, Formula 1’s tire supplier since 2011, invited us down to this year’s United States Grand Prix at the Circuit of the Americas outside Austin, Texas, so that we could get some face-to-face time with Pirelli’s Motorsports Director, Mario Isola. With the scent of freshly-mounted rubber in the air and Formula 1 cars warming up in the garage, there’s no better place to talk about tires.

“We always use Formula 1 to learn and to get data and to test our tires in the most stressful situation to learn technology for road tires.”

Besides the obvious brand-building and constant name exposure Pirelli gets from Formula 1, the many years it’s been in the sport help bring innovation to the consumer products on sports cars and regular everyday cars. That’s how racing works for manufacturers — win on Sunday, sell on Monday — and it’s no different for a tire supplier.

Because Formula 1 made the switch from 13-inch to 18-inch wheels this season, it brings Pirelli even closer to a street tire in terms of the data and possible learnings, but the past decade of 13-inch tires have still been fruitful. One of the areas where it has seen big improvements is tire modeling.

“With a 13-inch size, the size was so different that we got a good experience in virtual models, because when you have the technology in virtual models, then you can do that for road tires,” Isola says. “We now have simulators in Milan and we use the same approach for all the tires to make a virtual model of the tire and test it in the simulator. And then we are able to reduce the number of prototypes to bring on track.”

As every year passes, car manufacturers are getting better and better at computer modeling and computer simulation, thereby reducing the amount of real-world trial-and-error necessary. The same is true for Pirelli and Isola’s team. As Formula 1 forces you to innovate with new technology at a breakneck pace, that design process technology is able to be used to make tires like the Pirelli P Zero line.

When asked to point to specific characteristics of Pirelli road tires that were directly derived from Formula 1 technology, Isola dove into the tire bead. In case you’re new to deep dives on tires, the bead is the section of the tire that actually comes in contact with the rim and maintains that seal between said tire and rim.

“The bead of the P Zero, for example, the geometry of the bead of the P Zero is the same geometry that we have in Formula 1,” Isola says. “Obviously in Formula 1, the torque that we have here is crazy huge, and you need to be sure that you don’t have any rim turning between the tire and the rim. So it was really important to find the geometry of the bead able to seal the tire on the rim to avoid any sliding.”

If you were wondering why the bead is so important for a tire like the P Zero, Isola has an answer there, too.

“It’s not just a performance issue,” Isola continues. “Because obviously, if you have this sliding, you lose performance, but if you unbalance the tire you can generate a lot of vibrations, and it was really important to find a good solution for that. So, we made some finite, elemental analysis on the bead shapes and different geometries and then when we found the optimal one, that was used for all the tires.”

Beyond just the bead, Formula 1 has helped Pirelli innovate its production processes for some road tires. As an example, the Pirelli P Zero Trofeo R (and extreme, track-focused summer tire) is made using the same production process and on the same line as the Formula 1 tires.

“Actually, we have a new production process that we use for Formula 1,” Isola tells us. “And it’s used also for our ultra high-performance tires.”

You may also be wondering about what Pirelli has learned so far this season with the new 18-inch tires. We were, too, but unfortunately, it’s a little too early to make any grand conclusions.

“For the moment it is too early because this is the first year in with an 18-inch tire, but for the future, obviously our R&D engineers are in contact with R&D engineers for road tires,” Isola says. “And they talk very often. They exchange ideas and what we find in Formula 1.”

That said, Isola did give us a few hints about what it’s been able to do and what we’ll see from Pirelli’s learnings this year.

“So for the moment, what we are doing in the first year, we are using the 18-inch tire, so we are learning,” Isola says. “We are optimizing some parameters for next year. So we are working on this product now to optimize the pressure distribution, temperature, distribution under the footprint, the change in pressure because we have a delta pressure from cold to running temperatures, and all these new profiles and new criteria can be used for road tires.”

Once Isola has a few more years of running the 18-inch tire in Formula 1, the answers to our final questions might be a bit more interesting. Tire technology is constantly evolving, and those round bits of rubber holding us to the ground are anything but simple. We can’t wait to see what motorsports innovations are coming to the road next.

Related video: