AI and data science is transforming safety into a workplace benefit

The explosion of advanced technology in the workplace may seem like it’s right out of the novel Brave New World, but there’s real humanity in those applications. Artificial intelligence and data science tools can actually help transform worker safety from a business benefit into an employee benefit.

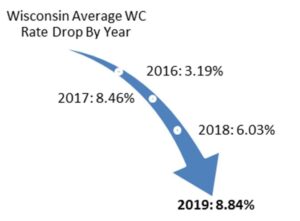

Keeping employee populations safe, of course, lowers risk and workers’ compensation insurance rates, improving productivity in the process, but it does so much more in a tight labor market and competitive business landscape. This is especially true for industrial settings where operating heavy equipment or lifting considerable weight can take its toll.

One of the most valuable lessons from the pandemic and Great Recession is the importance of building a culture around health and safety that shows that employers care about their people and will do whatever it takes to retain top talent.

Leveraging high-tech tools to improve workplace safety can improve operational efficiency. Of the $55 billion spent on workers’ comp in the U.S., just 2% of premiums are invested in safety, while as much as 71% is spent on claims. Overexertion and bodily reaction issues reportedly drive nearly half of all injuries in industries with frequent manual material handling.

Read more: Remote work makes workplace disaster plans essential

But there are many opportunities to reverse this, and benefit advisers can play an integral role in leading their clients down this path. With the help of AI and data science, we’ve been able to identify 22 causal risk factors that are visually detectable and drive 90% of workplace injuries. Major categories include ergonomics; being struck by equipment or objects; slip, trip and fall incidents; being caught in various hazards; and product damage from accidents or mishaps.

The trouble with most safety programs is that they’re reactive. Whoever is responsible for managing the work comp function and safety posture of an organization generally has to wait for accidents to happen before they can fix hazards. In short, they’re not able to make improvements until a trend of injuries and accidents has already been established.

The vast majority of these incidents are cumulative in nature, and there are countless examples of near misses and hazards that are putting people at risk every day. Having objective ways of measuring them and understanding the potential impact will bolster prevention and raise the bar on worker safety. That includes using benchmarks to identify the facilities and zones most in need of improvement, as well as updating operations scorecards with predictive safety key performance indicators.

Your employer clients most likely already have the video cameras needed that enable the scalable collection of objective data; internet connectivity and very inexpensive camera systems can gather all this video data from the workplace.

All an organization needs to do is upload the video — that makes it very easy for a company with the right AI technology to process that data quickly and generate objective metrics that benchmark various risk factors in that facility against facilities within the same organization or other companies with similar types of operations. This allows an employer to have enough context to create a predictive model that shares the likelihood of an accident based on the hazards and frequency of hazards seen inside facilities.

Read more: Why employers need a cybersecurity policy for their employees’ personal devices

AI has progressed to the point where two-dimensional video can produce thousands of data points that reveal when forklifts are endangering the lives of anonymized individuals, or more subtle safety risks from repetitive activities including how much time there is between cycles of stress on the body. AI can recommend strategies to eliminate that stress, even by simple changes like using a tool to improve one’s reach and avoid a hunched position.

Some of the most common and costly injuries that develop over the course of many years involve the lower and upper back, as well as neck and shoulder. Back injuries are often chronic and can last a lifetime, which is why it’s so important to address possible causes as early as possible before they turn into something that easily becomes a $1 million claim.

But it’s also important to address a human element to employee safety that’s often overlooked. Many blue-collar workers, especially in industrial-type jobs, live with pain daily and return home exhausted. They’re lifting 50 pound boxes hundreds of times a day and walking 20,000 steps, all of which they may be doing for years. Eventually, a significant portion of them end up becoming disabled to some extent and can no longer perform the work.

Preventing these tragedies, however, isn’t only a benefit to employees. There is also a benefit to businesses. What’s usually overlooked is the indirect costs of injuries, which can add two to five times the direct costs. They may include administrative overhead and lost production time involving employees who possess critical knowledge or skills, as well as recruiting and training costs.

Read more: 6 global business threats employers should plan for in 2023

Companies can do much better by their employees — and the bottom line. We now have the data and tools to look deeper than the injury numbers being reported to OSHA and claims processed through insurers. This allows us to gain a better understanding of the probability of accidents and source of risk, thereby giving us insight into how to eliminate the causal factors of workplace hazards.

Every company has a recruiting brand, not just a brand for customers. What they need to do is not just prevent injuries, but also protect employee wellbeing and quality of life. AI and data science provide a massive opportunity for employers to take workplace safety to the next level as a benefit.