1984 Mazda RX-7 GSL-SE Tested: Keeping the Sports-Car Faith

From the March 1984 issue of Car and Driver.

The Mazda people are different. Unlike the powers that be at most car companies, they seem genuinely to like sports cars. What’s more, they like them enough to understand them. They reject the assumption that two seats, a low-slung body, and a strong engine are all it takes to make a sports car. The RX-7 certainly has these features, but it also has that all-important sports-car magic. It sings an irresistible song, begging to be revved to its redline and thrown into corners, and it communicates the joys of the sports-car experience to its driver.

The first RX-7, in 1978, had the magic, but we couldn’t help wondering whether Mazda’s intentions were honorable. After all, several companies have sprung exciting new sports cars on us, only to dilute their sporting appeal in search of broader markets once their image-building potential was fully exploited. We’ve watched for such signs of degeneracy from Mazda, but as the RX-7 enters its seventh year of production, our worst fears have yet to be realized.

In fact, the RX-7, in its new GSL-SE incarnation, is more sports car than ever. The SE designation heralds the arrival of a long-awaited power increase, provided by a fuel-injected, tuned-induction, six-port version of Mazda’s 13B rotary engine. With its 1.3-liter displacement and new technology, the 13B develops 135 horsepower at 6000 rpm and 133 pound-feet of torque at 2750 rpm, both healthy increases from the 101 horsepower at 6000 rpm and 107 pound-feet at 4000 rpm of the 1.1-liter 12A engine, which is still standard in other RX-7s. Moreover, although the power peaks are identical in both engines, the SE motor’s much lower torque peak represents a considerable flattening of the rotary’s traditionally peaky torque curve. Newfound thrust is present at all rpm.

Many manufacturers would have exchanged some of the new engine’s performance potential for better fuel economy by harnessing it to taller gearing, but such thinking is antithetical to the mission of a serious sports car. Mazda’s powertrain engineers kept the faith, leaving the RX-7’s overall gearing essentially unchanged. Fifth gear is a bit taller, but not enough to compensate for the thirstier engine; the new SE returns 18 mpg (EPA city), while the lesser RX-7s are rated at 19. Neither figure is particularly impressive, but the SE’s penalty is modest relative to its power increase.

Having chosen not to hamstring the new engine with tall gearing, Mazda wasn’t about to shortchange its potential with weaknesses in the chassis. Four-wheel disc brakes, which have been fitted to all GSLs for the past three years, are upgraded on the SE with rotors that are nearly an inch larger and vented in the rear as well as the front. In addition, a larger master cylinder and a bigger brake booster firm up the braking action. The SE’s clutch is stronger, more heat-resistant, and damped by 10 percent more force to transmit the increased torque reliably. Power steering is offered for the first time in an RX-7, as an option on the SE; the amount of assist decreases with speed. Recognizing the importance of the tire-road interface, Mazda’s chassis engineers fitted the SE with top-class Pirelli P6 tires, in a generous 205/60VR-14 size, on wheels one inch larger in diameter than before.

In addition to these SE-exclusive features, all 1984 RX-7s benefit from several improvements. The chassis mounting points for the rear axle’s lower trailing links have been dropped by 0.8 inch to provide some roll understeer in the rear suspension. New slits in the front air dam increase cooling airflow to the front brakes. Inside, the instrument cluster, the steering wheel, the heater controls, and the minor switches have all been revised, and the storage bins behind the seats now have locking lids and interior illumination.

To the serious sports-car buyer these are extraneous details, mere trimmings around the main course, which in the SE’s case is its engine. The special flavor of the big rotary is not readily apparent, however, even to the sports-car gourmet, for the SE doesn’t seem drastically stronger than previous RX-7s. There is no violent kick in the back, no uncontrollable wheelspin, no primeval noises. Nor is there any of the loss in agility or the subtle increases in control efforts that so often accompany substantial power increases.

The SE does cover ground quickly, though. Dialing up high speeds on the speedometer requires little effort, the car going about its brisk business with little prodding from the shifter. Top gear suffices easily for most normal driving situations. And legging the throttle through the gears to the 7000-rpm redline quickly produces license-threatening speeds. Despite weighing 110 pounds more than our last RX-7 GSL, our test SE sprinted from a standstill to 60 mph in just 7.8 seconds, 2.6 seconds quicker than the earlier car. Its quarter-mile performance of 15.9 seconds at 86 mph was 1.5 seconds and 7 mph better. It hit 100 mph more than ten seconds sooner, in 23.9 seconds. The SE’s low-rpm muscle was evidenced just as clearly, with times of 10.5 and 11.0 seconds in the 30-to-50-mph and 50-to-70-mph top-gear runs, about three seconds better in each case. Top speed climbed from 118 to 125 mph.

Such performance easily puts the SE into the ranks of seriously fast cars, yet it feels hardly quicker than a good four-banger sports sedan. The reason is that Mazda’s engine engineers spread their torque out as flat as frosting on a cake. It’s an engineer’s dream that’s seldom realized: The big rotary produces very nearly the same torque at all engine speeds, so no sudden surge is felt when the torque curve peaks. This even temperament, combined with the rotary’s silky smoothness, kitchen-blender hum, and consistent throttle response, results in a flow of power so linear that it’s deceptive. The driver need only use the gearbox to dial up the proper rpm between 1000 and 7000 for any desired thrust. Without the response glitches, holes, and rushes common in most other power curves, the SE’s engine is a model of predictability.

George Lepp|Car and Driver

It’s a good thing the engine is so forgiving, because it enables you to control the chassis’s traditional penchant for hanging its tail out at the limit. When the car is first pitched into a corner at speed, the tail steps wide and then catches a grip on the pavement. The cornering response is then linear, with a noticeable bias toward oversteer that encourages tail-out driving. Total grip does benefit from such chassis balance, since the cornering effort is quite evenly divided between the front and rear tires. Indeed, with the help of the Pirellis, the SE generated an impressive 0.82 g on the skidpad, balanced on the fine edge of oversteer.

This balance is easy for a driver to achieve, because the SE communicates its every move through a suspension biased more toward information than plushness. Small imperfections are absorbed surprisingly well, but medium-size bumps don’t seem to deflect the suspension at all. The new power steering also helps keep the SE pointed in the right direction: It has good feel and a much faster ratio (3.1 turns lock-to-lock instead of 4.3) than that of previous RX-7s, although on-center precision is still lacking. The upgraded brakes are improved in every respect, with better balance, feel, and fade resistance.

These characteristics may not sound like the ultimate in handling sophistication, but the SE is actually a ball to drive hard. The strong engine lets you kick the tail out at will, and the linear throttle response and the predictable chassis behavior let you hold it at any desired attitude without trauma. On wet pavement the SE can make quite a scene, lighting up its tires in the first three gears if you so desire. Entire blocks can be covered sideways.

Despite the SE’s sporting orientation, it shares all the luxury amenities introduced in GSLs three years ago. The driver is pampered with cruise control, electric mirrors, electric windows, air conditioning, a good stereo system complete with an equalizer and a joy-stick balance-and-fader control, and a sunroof. The comfortable driver’s seat now offers a height adjustment; leather is available as an option. The new instruments provide the necessary information in a more logical array than before, the steering wheel is a proper three-spoke unit, the visibility is panoramic, the control layout is admirably handy, and the driving position is excellent in every respect, down to a welcome dead pedal. Our only interior quibble concerns the bright surface finish of the vertical panel in the central console; a matte-black finish would be more appropriate for a car of such sporting persuasion.

George Lepp|Car and Driver

With a complaint list so short, it’s clear to us that the RX-7 GSL-SE is the best and sportiest RX-7 ever offered to the American driver. At a base price of $15,095, it’s also the most expensive. That’s a full two grand more than a regular GSL, and quite a sum for a car that made its reputation on exceptional affordability; at this RX-7’s price level, there are now Supras, Starions, 300ZXs, and well-equipped V-8 Mustangs and Camaros to choose from. The GSL-SE, however, will handily outrun every import in its price class, and it’s much smaller, nimbler, and more economical than its big-motored American rivals.

What makes the GSL-SE so good is that Mazda has kept the sports-car faith. For the money, there still isn’t a better fling-about, redline-hungry, tire-smoking sports car to be had.

Technical Highlights

The RX-7 GSL-SE’s 13B rotary engine is only 14.1 percent larger in displacement than the 12A powerplant (1308 versus 1146 cc), yet it develops 33.6 percent more power and 24.3 percent more torque. Obviously, Mazda has done more than shoehorn wider rotors into the bigger motor.

Car and Driver

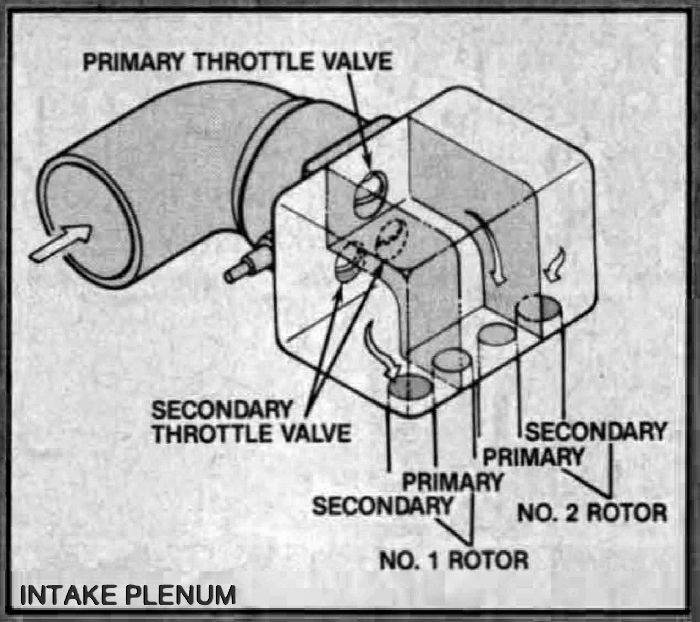

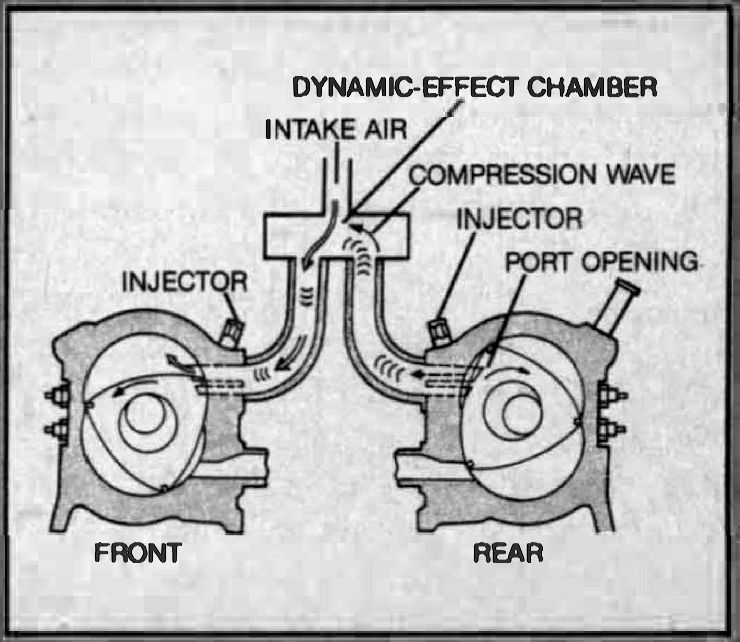

Better breathing accounts for the additional difference; a rotary’s output, like a piston engine’s, is limited by its airflow. Most of the improvement comes from a new intake system and port fuel injection, a combination that allows great flexibility in manifold design. The proven system of primary and secondary ports controlled by staged throttles is retained, maintaining high port velocities even at part throttle. Primary air is inducted through its own tuned passages, entering the front and rear combustion chambers through the center plate that separates the two rotors. Secondary air goes to the front rotor through the front-end plate and to the rear rotor through the rearmost end plate. In the 13B, the engineers have split the secondary flow path in two, so a total of three (one primary, two secondary) passages deliver air to each rotor. Fuel is sprayed in by one solenoid-type injector in each primary air passage.

The new third ports are opened by exhaust back pressure at high rpm. Their additional area and altered timing ensure efficient full-power breathing, allowing the main ports to be optimized for low-rpm performance.

Car and Driver

In addition to its three-stage porting, the intake manifold was designed to take maximum advantage of the rotary’s very strong intake pulsations (stronger than a piston engine’s, because the ports open more quickly and are not obstructed by valves). Two different pressure pulses are used to boost intake charging: The first occurs when an intake port has just dosed and the rapidly flowing intake-air column runs into a dead end; the second pulse is generated by the residual pressure escaping from the combustion chamber when an intake port first opens. Careful tuning of the dimensions and configuration of the intake manifold can harness these positive-pressure pulses to force more air into the combustion chambers; in the SE rotary, the tuning was optimized for low-speed breathing. The result is abundant torque, peaking at 2750 rpm in the 13B, far below the 4000-rpm peak of the 12A.

Oil is injected into the intake-manifold plenum in conventional Mazda fashion, but the 13B receives additional apex-seal lubrication from oil injected directly into the trochoid chambers. The rotor-housing surfaces are chrome-plated, like the 12A’s, but have a harder finish and improved porosity for better oil retention, giving the 13B durability to match its muscle. —Csaba Csere

Kenichi Yamamoto:

A talk with the stepfather of the rotary engine.

“I felt a genuine surprise when I first saw a running prototype of the rotary engine in 1961. It was so compact and turning so smoothly. Like any engineer, I was impressed by the novelty, because there was so little variation in internal-combustion engines at the time. I felt a passionate desire to challenge and perfect the rotary engine.”

These days, we hear a lot about the strength of the Japanese character. Kenichi Yamamoto, Mazda’s 61-year-old senior managing director in charge of advanced technology, research, and development, is a living example of what all the talk actually means: commitment to ideals, perseverance, and personal sacrifice for the greater good. Yamamoto may not be the natural father of the rotary engine, but he did act as a loving foster parent in developing Dr. Felix Wankel’s invention to the high level of refinement it enjoys today.

Car and Driver

Lest we forget, the Wankel is this century’s only new automobile engine. The Rankine (steam), Otto cycle, and diesel engines were all patented before 1900; since then, the Wankel is the only newcomer to earn commercial success. It’s equally remarkable that both the rotary engine and Mazda have blossomed in only a quarter of a century. Felix Wankel’s engine first ran in 1957, while Mazda was struggling to regain a footing after the war by manufacturing three-wheeled trucks. The firm’s first four-wheeled vehicle wasn’t rolling until a year later, and its first automobile—a 900-pound, two-seat coupe powered by a 360 cc piston engine—didn’t go on sale until 1960.

Yamamoto explains: “Mazda was a latecomer to the passenger-car field. We needed new technologies to challenge some very severe international competition. The late Tsuneji Matsuda, who was Mazda’s president during the birth of our first automobiles, had always been receptive to new ideas, and he saw the rotary engine as an advance investment in Mazda’s future. I was then an assistant manager of automobile design, and, frankly speaking, I was a bit skeptical at first about the engine’s practical potential. My experience had been exclusively with reciprocating engines. I had learned the hard way how complex the mechanical requirements of automotive engines could be.”

The “hard way” is an apt description of Yamamoto’s early career. He graduated from Japan’s Imperial University (later renamed Tokyo University) in 1944, with a degree in mechanical engineering, only to be snapped up by the navy to supervise the production of kamikaze aircraft. After World War II, he returned to his hometown, Hiroshima, and found most of it leveled by the atomic bomb. Luckily, his home was spared, along with one major industrial firm: Toyo Kogyo, the company that would later build Mazda automobiles.

Jobs were few and far between in Hiroshima, so Yamamoto took what he could get, a laborer’s position on Toyo Kogyo’s assembly line. He bolted together truck transmissions for a year and a half, work that was physically and mentally taxing. Finally, his technical talents were noticed, and he escaped the factory floor for a job in the engine-design department. There Yamamoto quickly filled his portfolio with one successful engine design after another.

Mazda began studying the Wankel engine’s potential in 1960 and signed a technical agreement with the patent holders a year later. Believing the engine would help the firm to establish an identity quickly, president Matsuda asked Yamamoto to form a new rotary-engine division at the end of 1962. Out of admiration and respect for his president, Yamamoto pledged his support to the unproven engine.

“In the beginning, we experienced lots of difficulties. Some were technical, others were not. Since we had announced to the world that we were undertaking rotary-engine development with the intention of building and selling engines, many people, both inside and outside the company, voiced strong criticism before they saw any results. Therefore, whenever the young engineers were discouraged by technical problems, they were also disappointed by outside criticism. I had to not only spur them with technical ideas, but I also had to keep their morale high and give them hope. Fortunately, Toyo Kogyo management had decided the new technology was indispensable. The challenge was difficult, and I was forced to work more than the young people in my division to stay ahead. In fact, I made a point of placing a notebook beside my pillow at night so that when any new idea dawned on me I could write it down. Almost every evening I woke up and jotted down some note; then the next day I’d call a meeting and challenge the young people with a new or better idea. If the engineers saw an enthusiastic leader, they responded with greater passion. I challenged each one to come up with at least one new idea every day, and I promised that I would do likewise.”

Yamamoto also insisted that his staff learn English and use it in group discussions so that every engineer would get the most out of international technical meetings. “In the beginning, the Wankel family was made up of an international group that exchanged information. Our common competitor was not another company, but rather the piston engine. I clearly remember once when the enthusiastic president of NSU, Dr. Ing. von Heydekampf, called out to all of us to band together and create a new engine that would go down in history. While I knew there were difficulties ahead, I was deeply touched in that room of engineers from all over the world, and I felt certain the project would succeed.

“As time went on, however, many of the rotary-engine proponents dropped off, and I started to feel lonely and disappointed. Nevertheless, we received many letters from engineers around the world interested in our work. We felt we were being watched. That gave us pleasure and encouragement, and we made up our minds to live up to those expectations.”

In 1967, after less than five years of rotary-engine development, Mazda introduced the 110S (a.k.a. Cosmo Sports) two-seater with a 110-hp, two-rotor powerplant. Since then, 1.3 million rotary engines have been manufactured by Toyo Kogyo. There have been ups and downs. The RX-7 is an unqualified success today, but O-ring-seal failures were common during the early Seventies, and there was a crash program after the first energy crisis to improve the rotary’s fuel efficiency.

Yamamoto is now a senior member of the board of directors and as eager as ever for the rotary to prevail against stronger competition from gas and diesel piston engines. “We would like to perfect TISC [timed induction with supercharge] for production. This uses a compact compressor combined with inherent rotary-engine characteristics to improve low- and mid-range torque. Of course, we are also engaged in several step-by-step developments: improvements in gas seals, reduction of internal friction, and better cooling, to name three. The rotary is still quite attractive to us, because there is so much potential for improvement. An engineer can maintain his dream of finding out new things.” —Don Sherman

Specifications

Specifications

1984 Mazda RX-7 GSL-SE

Vehicle Type: front-engine, rear-wheel-drive, 2-passenger, 3-door coupe

PRICE

Base/As Tested: $15,095/$16,125

Options: leather interior, $720; power steering, $310.

ENGINE

2-rotor Wankel, electronic fuel injection

Displacement: 80 in3, 1308 cm3

Power: 135 hp @ 6000 rpm

Torque: 133 lb-ft @ 2750 rpm

TRANSMISSION

X-speed [automated] manual/[dual-clutch] automatic/continuously variable automatic/direct-drive

CHASSIS

Suspension, F/R: struts/rigid axle

Brakes, F/R: 9.8-in vented disc/10.1-in vented disc

Tires: Pirelli P6

205/60VR-14

DIMENSIONS

Wheelbase: 95.3 in

Length: 170.1 in

Width: 65.7 in

Height: 49.6 in

Passenger Volume: 46 ft3

Trunk Volume: 8 ft3

Curb Weight: 2590 lb

C/D TEST RESULTS

60 mph: 7.8 sec

1/4-Mile: 15.9 sec @ 86 mph

100 mph: 23.9 sec

Top Gear, 30–50 mph: 10.5 sec

Top Gear, 50–70 mph: 11.0 sec

Top Speed: 125 mph

Braking, 70–0 mph: 199 ft

Roadholding, 200-ft Skidpad: 0.82 g

C/D FUEL ECONOMY

Observed: 22 mpg

EPA FUEL ECONOMY

Combined/City/Highway: 22/18/29 mpg

C/D TESTING EXPLAINED