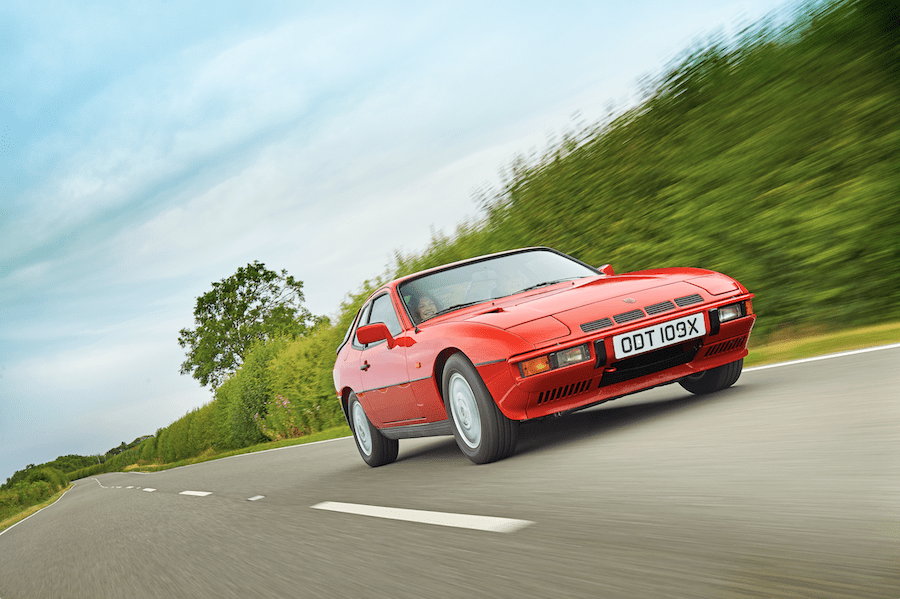

Restoring a rare Porsche 924 Turbo to its former glory after an accident

Fresh from the pages of Practical Classics Magazine, we meet Glen Williams, who has restored his father’s rare Porsche 924 Turbo, five years after a heavy crash and Lewis Buchan, who gave his Reliant van a new lease of life.

As a specialist classic car insurance broker, we love seeing old cars being restored to their former glory, which is why we’ve linked up with Practical Classics to bring you two fantastic stories each month for you to digest and take as inspiration for your own classic rebuilds.

Restoring my father’s rare Porsche 924 Turbo after a heavy crash

Words by Nigel Clark and Pictures by Matt Howell

By serial restorer Glen Williams’ own admission, this stunning Porsche is a car that probably shouldn’t have survived. The fact that it’s still here is due to two factors: Glen’s extraordinary restoration talent, and the strength of the bonds within the Williams family.

The story begins in 1998, when Glen’s father David was looking for a sports car and spotted this Guards Red 924 Turbo on the forecourt of a nearby dealer. He thoroughly enjoyed driving the Porsche for almost twenty years before disaster struck on an oily roundabout.

The resulting accident caused extensive damage, front and rear, though fortunately no one was hurt. The battered Porsche was recovered home and soon afterwards the insurer declared it as a Category C write off, beyond economic repair. David loves his Porsche and couldn’t bear to see it go. Glen’s mother and father knew their son had the skills to repair the car – he had already restored numerous Triumphs and an MG, so they implored him to restore it for them.

Thus began a project that was to take nearly five years. Why so long to repair a bit of accident damage? Glen provides a compelling reason: “I don’t have a garage or a workshop, so the restoration had to be carried out under my father’s carport, 15 miles from my home, which meant packing up all my tools to take every time I worked on dad’s car.”

Worse was to come as Glen found “once I started stripping the car, almost everything was either damaged, rusted to the point of being unsafe or simply worn out”. Then Covid-19 struck, causing further delays. In Glen’s words: “The project had evolved into a monster.”

Glen got straight into the job, planning for a limited body rebuild front and rear. At the weekends he removed the damaged panels, while his evenings were spent scouring the internet for replacement parts. As he cut away the outer panels, the extent of the rust problems hidden beneath became all too apparent and he ended up stripping the car to a bare shell within the space of a few months.

An example of the horrors uncovered during the strip down, Glen says “the rear suspension torsion beam was hanging by just a thread, as the mounts had completely delaminated.” He has plenty of cost saving advice gained when searching for rare parts and made extensive use of the internet. “Joining the Porsche 924 Owners Club forum was a huge help,” Glen declares, as it enabled him to track down sources for parts that are officially no longer available.

Starting at the front, Glen had found the 924 Turbo’s unique front panel simply wasn’t available anywhere. He carefully removed the original panel from the bent front-end and painstakingly beat the panel back into shape. Such is his skill, today one could never tell just how badly bent the nearside corner of this prominent piece of bodywork once was. The remainder of the front end panelwork, including the wings, was salvaged from other scrapped 924s.

The Turbo bonnet with its unique air scoop came from America. Moving rearwards, a dented door was replaced with a secondhand one, but the extensively damaged rear end proved much more difficult.

Though the rear of the Turbo body is the same as other 924 models, the extent of the damage and corrosion still provided enough of a challenge when he came to repair it. Through the Porsche 924 Owners forum, Glen learned of a complete car being broken for spares in Coventry, with a body shell available for £200. He grabbed his power saw, jumped in a van and went to look. What he found was a straight, relatively rust-free shell. Rather than struggle to bring the whole shell home, he neatly cut off the rear section he needed plus a margin and loaded it into the van.

Back home, Glen could cut away all the bent bodywork from the rear of his father’s car and graft in the new-old rear end section salvaged from Coventry. That brief description makes the job sound easy but ever the perfectionist, Glen had to get this transplant surgery spot on.

After multiple measurements and drilling out old spot welds dating back to factory assembly, the new rear end could be offered up and trimmed to an exact fit, before more measurement and tack welding.

After grinding the welds clean, Glen finished the repair with meticulous lead loading, forever sealing and smoothing the joints. The result is a cut-and-shut job so neat that it’s simply invisible. The fit of the grafted-on inner panels was so good, the genuine Porsche new-old-stock rear wings Glen found in France fitted perfectly.

The rest of the body was neatly repaired with fresh steel wherever rust had broken out, before Glen sent it off to local specialist Mozza’s Body Repairs for final finishing and painting. The paint was the only job he farmed out and he says, “I have painted cars before and know how much time has to go into achieving a first class result. Sending the repaired shell to Mozza’s was an easy decision. It’s now finished in two-pack Porsche Guards Red and sealed with a clear lacquer, which provides an amazingly deep gloss and will hopefully ward off the dreaded colour fade, for which solid red paints are notorious.”

While the body was away at the paint shop, Glen busied himself refurbishing suspension, brakes and pretty well everything else that would need to be refitted later. Many more evenings were spent trawling the net for the cheapest sources of the multitude of parts required. Suspension parts were cleaned, painted and re-bushed, brake components were overhauled and calipers painted, steering thoroughly checked and new fasteners sourced ready for final assembly.

Always aiming for that ‘factory fresh’ look, he sent all the engine bay fasteners and brightwork for replating or passivating. Everything from the original car that was destined to be refitted has been deep cleaned, painted or plated, with the result that, whether under the car or in the engine bay, this Porsche appears to have rolled off Audi’s Neckarsulm production line yesterday rather than more than four decades ago!

By the start of 2020, the freshly painted body was back home under the car port and Glen was busy operating a one-man assembly line, refitting the bare shell. Always a nerve-wracking process when pristine new paint could so easily get scratched, he took his time… until the pandemic and the first lockdown prevented him visiting his parents’ carport.

Valiantly keeping the project moving, he turned to the engine. It had been rebuilt at 90,000 miles, but needed refreshing to bring it up to Glen’s standard for the rest of the restoration. Again, he spent time sourcing parts online, with crankshaft bearings proving particularly difficult. In addition to the bearings, the engine has new gaskets and oil seals throughout of course, and the eight valve cylinder head was refaced.

As the restrictions of lockdown finally eased, it was the summer of 2020 before the engine rebuild was completed, including another delay to find a replacement turbocharger housing to replace the cracked original. He finally sourced a good used turbo from America, where the majority of 924s were first sold. Like the rest of the car, the engine is now immaculate, inside and out.

By autumn, dad David’s Porsche was nearly done. Getting the engine running right was the biggest challenge as he wasn’t familiar with the Bosch K-Jetronic fuel injection system. Eventually, rough running was traced to the warmup regulator. Once that had been overhauled, the Porsche’s complex turbocharged engine ran sweetly and pulled like a train.

Now satisfied with the Porsche’s as-new condition, Glen handed it back to his father in July 2021, albeit with non-original replacement seats in brown vinyl.

Sadly, having suffered a stroke, David hasn’t yet been able to drive his restored car, but the family are naturally hoping that moment will come soon. The final detail of the restoration was earlier this year, five years after the project began, when Glen replaced the brown vinyl covers on the front seats with new ones, made from the original Porsche fabric by Nine Series Classics.

The seats really are the finishing touch on a monster of a restoration project that is remarkable in both its quality and its faithfulness to originality. It’s yet more extraordinary to consider this was achieved under a carport, miles from Glen’s home, in all weathers and through a global pandemic. It may not be Glen’s familiar Triumph territory, but this Porsche 924 Turbo is a triumph for his restoration skills and the strength of family ties.

Read the full version of how Glen managed to restore this rare Porsche 924 Turbo on the Practical Classics page.

Transforming a Reliant van into a ‘supervan’

Words and Pictures by James Walshe

When you find a car covered in weeds and brambles, you can’t just walk away, can you? That’s how Lewis Buchan felt when he found this Reliant in 2020. Here he tells us his story on how he gave this van a new lease of life.

“It’s a 60,000-mile 1971 Supervan III, which I bought during the first pandemic lockdown after spotting it in a picture on Facebook. You could just about see it, nestling in the bushes and, being a Reliant man, I had to have it.

“A month later, I travelled to a remote location near Aberdeen where I was shown to the car, which was hidden in a field full of weeds, and was becoming part of a hedge! The reason for it being there was a mystery. I noticed straight away the van was Aberdeen registered, but there was no evidence of signwriting on the back. No clues at all.

“What I did know, however, is that I would be restoring it. I have a workshop at home, so I was confident I could revive this Supervan III. It’s a version I’ve always wanted, so I had the motivation to get the job done!

“When I got it home, there was very little chassis left and the engine was missing. It didn’t worry me though, as I had a few spare engines that were period correct for this model. I set about removing the remains of the chassis. Somebody had previously taken an angle grinder to it, for some reason. I bought a scrapped chassis, took all the dimensions for the missing parts, made notes of the profile and mounting points for the suspension, and the welding commenced! If the outriggers are even slightly off, it’s enough for the body not to sit properly on the chassis.

“I worked on both chassis and bodywork simultaneously. One day, I’d do glass fibre repairs and the next night I’d tackle the metalwork! Thanks to previous restorations, I had experience with glassfibre, so it was second nature really. The shell was sound enough as a whole with a few holes to cracks throughout. Anything is possible with glass fibre though!

“The front bumper area is vulnerable, with chunks missing on many Regals and Supervans. Mine was damaged, so I began by using clamps to hold everything in place and got the Frog Tape out. I cover the gaps and cracks in the tape on the outside, and then apply the glass fibre from the inside out, then peel away the tape. I’d like to say I did the paint but I’m still learning how to do that.

“I had a rummage around my spares stash and dragged out a seized 700cc engine, correct for this van, and rebuilt it. I spent quite a lot of money on new parts for it, as I wanted the engine as good as it could possibly be. There were also some useful bits on the spare chassis, including a brake pedal assembly, clutch pedal assembly and clutch rod – so I refurbed all of that and then stripped the rear axle assembly and revived all the components on the bench.

“It’s such a satisfying feeling when the shell goes back onto a fully refurbished chassis and you bolt it down and connect everything up. But then comes the moment when you fire the car up for the first time!

“It’s well worth taking as many pictures and as much video footage as you can, too. I captured that first start on video – so I can relive the moment again when I need motivation to finish my next project!”

Read the full version of how Lewis gave his Supervan a new lease of life on the Practical Classics page.